DESCRIPTION

Inconel 625 wire and bar (UNS N06625) to AMS 5666, AMS 5837, ASTM B446, and NACE MR0175 is a Nickel-Chromium-Molybdenum-Columbium (Niobium) alloy with excellent oxidation resistance, corrosion resistance, and strength at high temperatures. The alloy does not require age-hardening treatments to obtain the high-strength properties due to the solid solution effects of molybdenum and columbium on the nickel-chromium matrix. This wire is resistant to chloride-ion stress-corrosion cracking, pitting, and stress-corrosion cracking making it suitable for seawater applications. This alloy can operate from cryogenic temperatures up to 1800°F (980°C).

Applicable Specifications

Wire & Bar:

AMS 5666, AMS 5837, ASTM B446, AWS A5.14, NACE MR0175 (ISO 15156-3), NACE MR0103/ISO 17945.

Applications

Inconel 625 wire and bar is commonly used for springs, seals, nuclear water reactors, and aircraft ducting systems.

Industries Supplied

625 is often used in corrosive environments such as Marine, Chemical Processing, and Aerospace.

Nominal Composition

Ni: 58.0 min

Cr: 20.0 – 23.0

Mo: 8.0 – 10.0

Cb (Nb): 3.15 – 4.15

Fe: 5.0 max

Co: 1.0 max

Si: 0.5 max

Mn: 0.5 max

Al: 0.4 max

Ti: 0.4 max

C: 0.10 max

Physical Properties

Density:

0.305 lb/in3, (8.44 g/cm3)

Modulus of Elasticity (E):

At 70°F (20°C): 30.1 x 103 ksi (208 GPa)

Modulus of Rigidity (G):

At 70°F (20°C): 11.8 x 103 ksi (81.2 GPa)

Coefficient of Expansion:

7.4 µin/in.-°F (70°F to 600°F)

13.3 µm/m-°C (20°C to 300°C)

Electrical Resistivity:

50.8 µΩ.in, (129 µΩ.cm)

Thermal Conductivity:

68 Btu-in/ft2hr-°F, (9.8 W/m-K)

Typical Mechanical Properties – Spring Applications

Annealed

- Heat Treatment: 1925°F (1050°C)

- Tensile Strength: 120 – 150 ksi; (830-1100 MPa)

- Suggested Operating Conditions: -300°F to 700°F (-184°C to 370°C)

Spring Temper

- Tensile Strength: 200 – 240 ksi; (1380 – 1655 MPa)

- Suggested Operating Conditions: -300°F to 700°F (-184°C to 370°C)

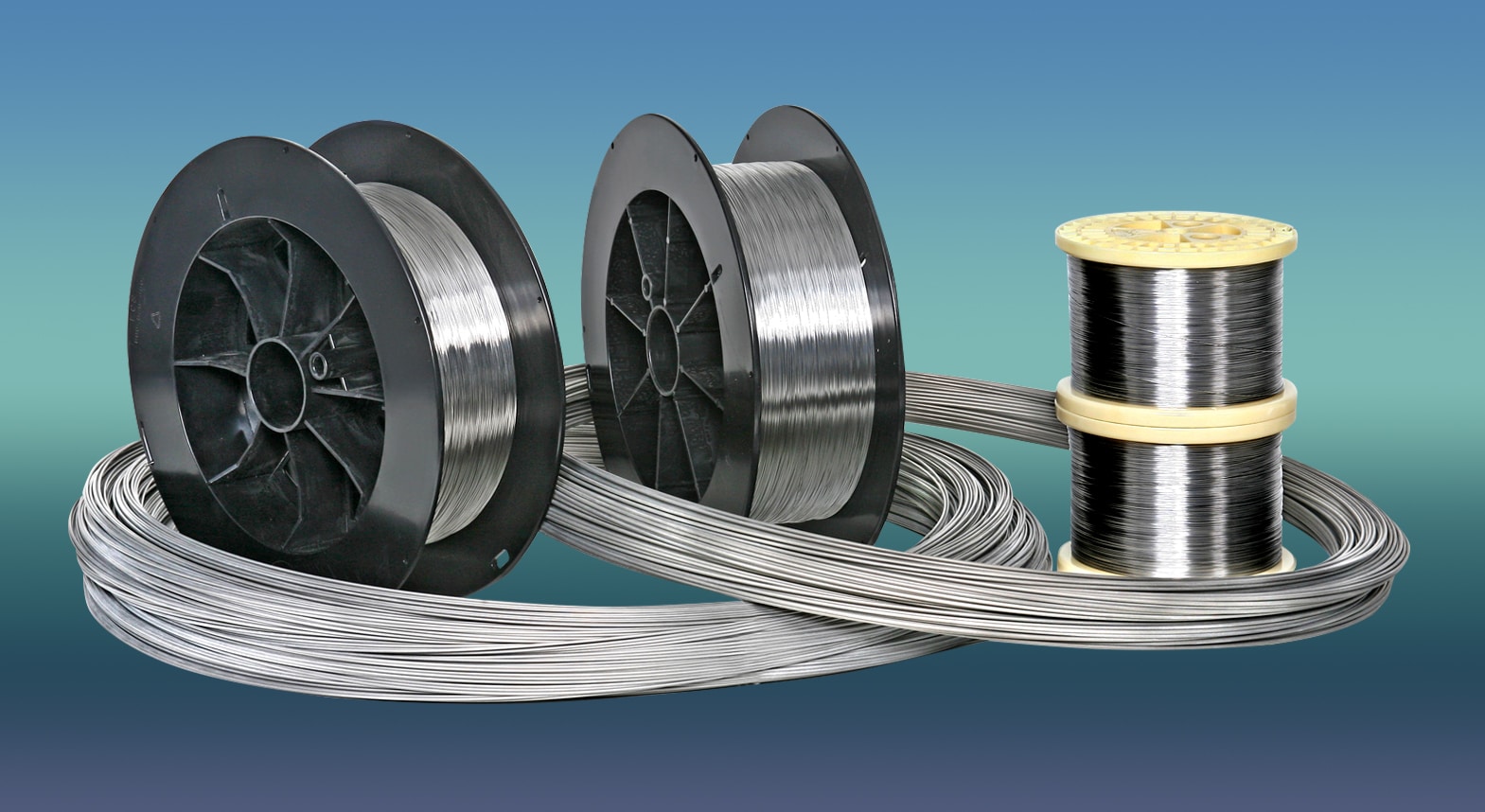

Inconel® 625 Wire Alloy

Inconel® 625 wire is available in round, flat, or shaped wire. The nickel alloy offers great resistance to oxidation and its scaling at very high temperatures. Alloy 625 is often preferred over other alloys providing resistance to extreme temperatures. The makeup of nickel 625 wire also makes it able to withstand corrosive environments. There is almost no impact on the wire in fresh or even salt water. This also holds true for non-acidic environments. The high levels of Molybdenum also allows the alloy to be very resistant to pitting.

Added Niobium

Further analysis into the wire alloy shows that the aversion to corrosion and oxidation is due to the presence of Niobium. The Niobium also adds to strength and toughness allowing it to function in extreme conditions.

Good Fatigue Strength & Stress Corrosion

The alloy has a good fatigue strength and stress-corrosion cracking resistance to chloride ions, which is why oxidation and corrosion is so rare. Nickel 625 is also flexible, both in its side-to-side mobility, and the variety of places that it can be used.

Saltwater Environments

Inconel® 625 wire is commonly used in marine and saltwater environments. The salt level contained in ocean and sea waters normally has a degrading effect on any metal that spends a long period of time in it.

Resistance to Steam Corrosion

The 625 alloy also withstands steam, extreme heat, or natural corrosion that comes from water. This makes it ideal for exhaust systems, ducting systems, engines, and chemical processing equipment.

Less Creep Corrosion

Inconel® 625 wire is able to withstand challenging environments because of its chemical content. It was originally formulated for steam-line piping. Its chemistry makes it resistant to creep properties at both low and high temperatures. Creep conditions happen when high temperatures are met with applied stress. Niobium, an element added to 625 alloy helps prevent creeping.

At Elgiloy, we use flexible and custom manufacturing which allows us to provide our customers with the exact amount and shape of Inconel® 625 wire alloy they need. We rigorously inspect and will meet the already very high expectations that you have for the product. Because of the challenging environments, this wire must perform in, it is necessary to make sure that it can stand up to many conditions. Our engineers make sure that all qualifications are met, and that all of our customers, international or domestic, are receiving wire that they can trust and rely upon.

Inconel® is a registered trademark of the Special Metals Corporation group of companies.

For further information Contact:

CONTACT US

Phone: 1.847.695.1900

Elgiloy Specialty Metals – Wire Products

356 N.Cross Street

Sycamore, IL 60178 USA

Limitation of Liability and Disclaimer of Warranty:

- The content in these data sheets is provided primarily by third-party melting mills and is provided for reference only. It is not intended for engineering or design.

- Applications may be discussed, however, Elgiloy Specialty Metals, a Division of Combined Metals Company LLC, does not recommend or endorse any material for any particular end use or application.

- The data included in this data sheet are typical values and may vary.

- Elgiloy Specialty Metals, a Division of Combined Metals Company LLC, makes no representations or warranties, express or implied, as to the accuracy, completeness, condition, suitability, performance, fitness for a particular purpose, or merchantability of any information contained in any data sheet.

In no event will Elgiloy Specialty Metals, a Division of Combined Metals Company LLC, be liable for any damages whatsoever arising from the use of the information included in the data sheets.